Conductive & Anti-Static Plastic Compounds

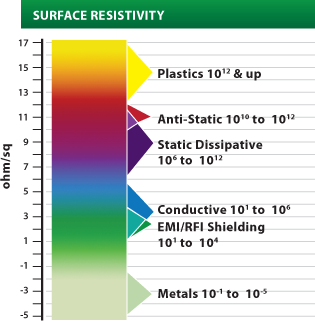

Surface Resistivity

- Provide static dissipation and ESD protection

- All-polymeric and particulate filled grades available

Conductive thermoplastic compounds offer reliability and value for applications that require dissipation of static charges, protection from electrostatic discharge (ESD), or thermal management.

Specialty compounds can be tailored to offer electrical properties spanning the surface resistivity spectrum from 100 to 1012 ohm/sq and formulated for injection molding or extrusion processing.

Multiple technologies are available to impart conductive properties into thermoplastic resins. Each offers different approaches to providing the exact degree of conductivity required for your application, whether anti-static, static dissipative, ESD protection, conductive, or EMI/RFI shielding.

In all-polymeric grades, conductive IDP polymers are alloyed with host resins, for others conductive particulate or fibers are combined with a base polymer to form a conductive matrix.

Anti-static and conductive plastic compounds have a number of advantages over metals or surfactant coatings. Finished parts are lighter in weight, easier to handle, and less costly to ship. Their fabrication is usually easier and less expensive due to the elimination of secondary processes, and they are not subject to denting, chipping and scratching.

Black is not your only color choice when working with conductive compounds, many can be colored for identification or aesthetic purposes, eliminating the need for secondary color processes. Some anti-static grades even offer transparency.