Thermoplastic Films

Thermoplastic Films

Business associates of SUGOI Polymers produces pinhole free flexible and rigid thermoplastic films and film laminates with up to four layers of film and fabric which includes:

- Thermoplastic Polyurethane (TPU)

- Polycarbonate (PC)

- PETG/Copolyester

- Acrylic (PMMA)

- Rigid and flexible PVC

- Polyolefins including Polyethylene, Polypropylene, and blends

- Ethylene Vinyl Acetate (EVA)

- And more… we can even toll manufacture films and laminates

from your compounds and fabrics!

Films can be produced in thicknesses ranging from 0.0005 to 0.1870 inch

(0.013 to 4.750 mm) and widths up to 60 inches (1524 mm).

Polymer Films

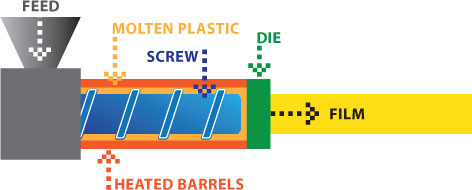

A broad line of high quality, custom engineered flexible and rigid thermoplastic films, produced through flat die extrusion for quality and consistency

Manufacturers who produce ultra high volume consumer goods such as trash bags and sign banners often use the blown film or calendering production processes to create “good enough” film at rates of thousands of pounds per hour.

For higher quality film, Our Associates uses the flat die extrusion process. Flat die extrusion enables tight tolerances, outstanding lot-to-lot consistency in surface quality and appearance, and pinhole-free film even down to the thinnest gauges.

In fact, many customers find that, working with us, they can reduce costs by reducing the film thickness specification for their application, since Wiman can produce the thinner version with no pinholes. Flat die extrusion also provides the flexibility to impart different finishes on each side of the film.

Our Business Associates have extensive expertise with polymers including, but not limited to:

- Rigid and Flexible PVC

- Polyolefins including Polyethylene, Polypropylene and blends

- Ethylene Vinyl Acetate (EVA)

- Thermoplastic Polyurethane (TPU)

- PETG/Copolyester

- Acrylic (PMMA)

- PLA biopolymer

- ABS

- Polycarbonate (PC)

- and more.

PLASTIC FILMS CAN BEMADE OUT OF DIFFERENT POLYMERS

LDPE

Low density polyethylene or LDPE is the largest volume commodity thermoplastic and cheapest packaging film which is used for a wide variety of applications. It is easy to process, and can be blended with other polymers and/or additives, like EVA, HDPE, LLDPE, fillers, pigments to alter its basic properties. PE film is soft, very flexible, clear and glossy and has good tear resistance and good moisture barier but only fair gas barrier properties. Some major disadvantages and limitations of LDPE are poor weathering resistance, difficult to bond and poor temperature capability.

LLDPE

Linear low-density polyethylene has similar properties as LDPE and is often used in similar applications. However, there are some differences, which makes LLDPE preferable for different applications. For example, LLDPE is selected for its higher tensile and impact strength and better heat sealability, whereas LDPE is often selected for its higher clarity, ease of processing and higher gloss.

ULDPE

Ultra low density polyethylene or ULDPE is a soft and very flexible thermoplastic that is often used for very specific film applications, such as stretch wrap, food packaging, health and hygiene. Compared with LDPE, ULDPE offers greater low temperature flexibility and flex crack resistance, and is ideal for applications where excellent optics, and high tear resistance is required. However, (unmodified) ULDPE has poor UV resistance and poor barrier properties, except for water.

MPE

Metallocene polyethylene or mPE is a low density polyethylene which is made by utilizing a metallocene catalyst. This technology results in resins with very pure, and consistent properties. mPE films exhibit fast hot tack similar to EVA, which allows for rapid sealing. It has excellent puncture resistance and permeability to oxygen and good tensile strength at break and is much stronger than ordinary polyethylene. For many applications, mPE is a suitable alternatives to PVC and EVA.

HDPE

High density polyethylene or HDPE is a milky white, semi-translucent thermoplastic. It is flexible but more rigid and stronger than LDPE and has good impact strength and superior puncture resistance. It also has good chemical resistance and good vapor but poor gas barrier properties. HDPE film is often used in many of the same applications as LDPE and LLDPE. However, HDPE is stiffer than other polyethylene films, which is an important characteristic for packages that need to maintain their shape.

PP

Polypropylene or PP is a thermoplastic of high clarity, high gloss and good tensile strength. It has a higher melting point than PE, which makes it suitable for applications that require sterilization at high temperatures. The two most important types are cast unoriented polypropylene (CPP) and biaxially oriented polypropylene (BOPP). Both types have high gloss, exceptional optics, good or excellent heat sealing performance, high heat resistance, and good dimensional stability. In general, CPP has higher tear and impact resistance, better cold temperature performance and better gas barrier and heat-sealing properties, whereas BOPP has the higher tensile strength, higher modulus (stiffness), lower elongation, and lower haze.

PC

Polycarbonate (PC) is an amorphous engineering thermoplastic which has excellent mechanical, optical, electrical, and thermal properties. It is extremely tough and has outstanding impact resistance and high optical clarity. PC films are used for sterile medical packaging that require FDA approval and for film applications that require high scratch, chemical, and weathering resistance and high crystal clear transparency. Because of its higher price relative to PVC, PE, and PP film, it is generally considered a specialty film.

PVC

Vinyl film also known as polyvinyl chloride, or PVC is a versatile, cheap thermoplastic of good dimensional stability, good impact strength, and excellent weathering properties that can be easily die-cut and that is printable with conventional screen and offset printing methods. Depending on the composition, it can be clear or matt, colored or white, and rigid or flexible. Flexible vinyl film has good barrier properties to oil and grease but is oxygen permeable. It also has good puncture resistant and good cling and excellent clarity.

PET (BOPET)

Polyester film is a high-performance, crystal clear thermoplastic made from polyethylene terephthalate (PET). In comparison with other common plastic films, PET film has high tensile strength, excellent dimensional stability, low moisture absorption, and good retention of physical properties over a fairly wide temperature range. It also has superior UV resistance and excellent electrical properties, and good optical clarity. Because of its higher price relative to PVC, PE, and PP film, it is generally considered a specialty film.

PVDC

Polyvinylidene chloride (PVDC) is a synthetic thermoplastic produced by the polymerization of vinylindene chloride. The most common type is biaxial oriented film. PVDC has outstanding oxygen and moisture barrier properties comparable to aluminum foil and is resistant to many chemicals including grease and oil, which makes it ideal for food and medicine packaging applications to extend shelf life. It is also printable using common ink systems and provides excellent bond strength, high heat resistance, and low water absorption. PVDC is often used as a coating for other films to improve their gas barrier properties.

NYLON

Polyamide (PA), also known as Nylon, is a clear and printable thermoplastic that has a relatively high melting point, exceptional strength and toughness, and good oxygen barrier properties. It is also scratch, puncture, and flex-crack resistant and does not dissolve or absorb grease, oil, and acidic food. These properties make PA ideal for use in conventional and microwave cooking applications. The two most common types are cast and biaxial oriented Nylon film. Biaxial oriented polyamide or BOPA film can be used for a wide variety of applications especially where high gas barrier properties are required. Because of its higher price relative to PVC, PE, and PP film, it is generally considered a specialty film.